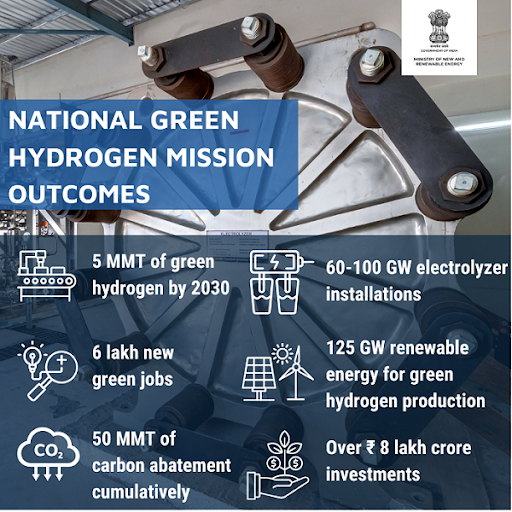

India aims to produce 5 million metric tonnes of green hydrogen annually by 2030, using renewable energy sources. The National Green Hydrogen Mission aims to boost production, develop infrastructure, and create export markets. Challenges include high costs, infrastructure gaps, resource constraints, financing hurdles, and environmental concerns.

Copyright infringement not intended

Picture Courtesy: NEWSONAIR

The Union Minister for Ports, Shipping and Waterways inaugurated the Green Hydrogen pilot plant at V.O.Chidambaranar Port at Tuticorin in Tamil Nadu.

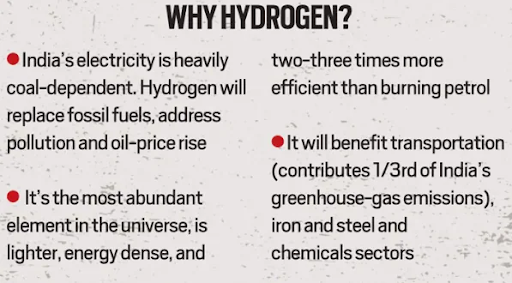

Green hydrogen is a clean fuel produced by splitting water into hydrogen and oxygen through electrolysis powered by renewable energy sources like solar or wind.\

Unlike grey hydrogen (from fossil fuels) or blue hydrogen (from natural gas with carbon capture), green hydrogen emits no greenhouse gases during production, making it a zero-emission energy carrier.

India aims to produce 5 million metric tonnes (MMT) of green hydrogen annually by 2030, with a potential to reach 10 MMT for exports.

National Green Hydrogen Mission (NGHM)

State-Level Support

States like Odisha, Tamil Nadu, and Gujarat offer incentives worth ₹5.05 lakh crore, 26 times the NGHM budget.

Decarbonization: Green hydrogen can replace fossil fuels in hard-to-abate sectors like steel and fertilizers, reducing emissions.

Energy Security: Local production reduces dependence on imported fossil fuels, enhancing energy independence.

Export Potential: India aims to supply 10% of global green hydrogen demand by 2030, targeting markets like Japan and the EU.

Economic Growth: Cumulative value of the green hydrogen market in India could reach $8 billion by 2030, and $340 billion by 2050. (NITI Aayog)

Global Leadership: Strategic partnerships with Saudi Arabia (via IMEC) and Japan (Clean Energy Partnership) position India as a key player in green hydrogen production and export.

High Costs

Infrastructure Gaps

Resource Constraints

Financing Hurdles

Environmental Concerns

Cost Reduction

Infrastructure Development

Demand Creation

Research and Innovation

International Collaboration

Green hydrogen is a game-changer for energy transition, offering a path to decarbonize industries, enhance energy security, and lead globally. By streamlining policies, boosting R&D, and promoting global partnerships, India can achieve its ambitious targets and emerge as a green hydrogen powerhouse by 2030.

Source: NEWSONAIR

|

PRACTICE QUESTION Q. Analyze the role of the National Green Hydrogen Mission in achieving India's climate action goals and reducing its reliance on fossil fuel imports. 150 words |

Green hydrogen is hydrogen produced by splitting water (H2O) into hydrogen (H2) and oxygen (O2) using an electrolyzer powered by electricity from renewable energy sources like solar, wind, or hydropower.

Unlike grey hydrogen (from natural gas, with CO2 emissions) or blue hydrogen (also from natural gas, but with carbon capture), green hydrogen has a near-zero carbon footprint in its production process.

The primary method is electrolysis, an electrochemical process where a current from a renewable source passes through water, breaking it into its constituent elements: hydrogen and oxygen.

© 2026 iasgyan. All right reserved