Rare earth magnets are high-performance materials essential for electric vehicles, wind turbines, electronics, and defence systems, making them critical for India’s clean energy transition and technological growth. With China dominating global processing, India’s push for domestic manufacturing, critical mineral processing, and recycling aims to reduce import dependence and build a self-reliant mine-to-magnet ecosystem to strengthen economic and strategic security.

Copyright infringement not intended

Picture Courtesy: The Hindu

India will commence domestic production of rare-earth permanent magnets within 2026, as announced by Union Mines Minister G. Kishan Reddy.

|

Must Read: RARE EARTH MAGNETS | RARE EARTH PERMANENT MAGNET MANUFACTURING SCHEME | TRADE WAR & RARE EARTH MINERALS | |

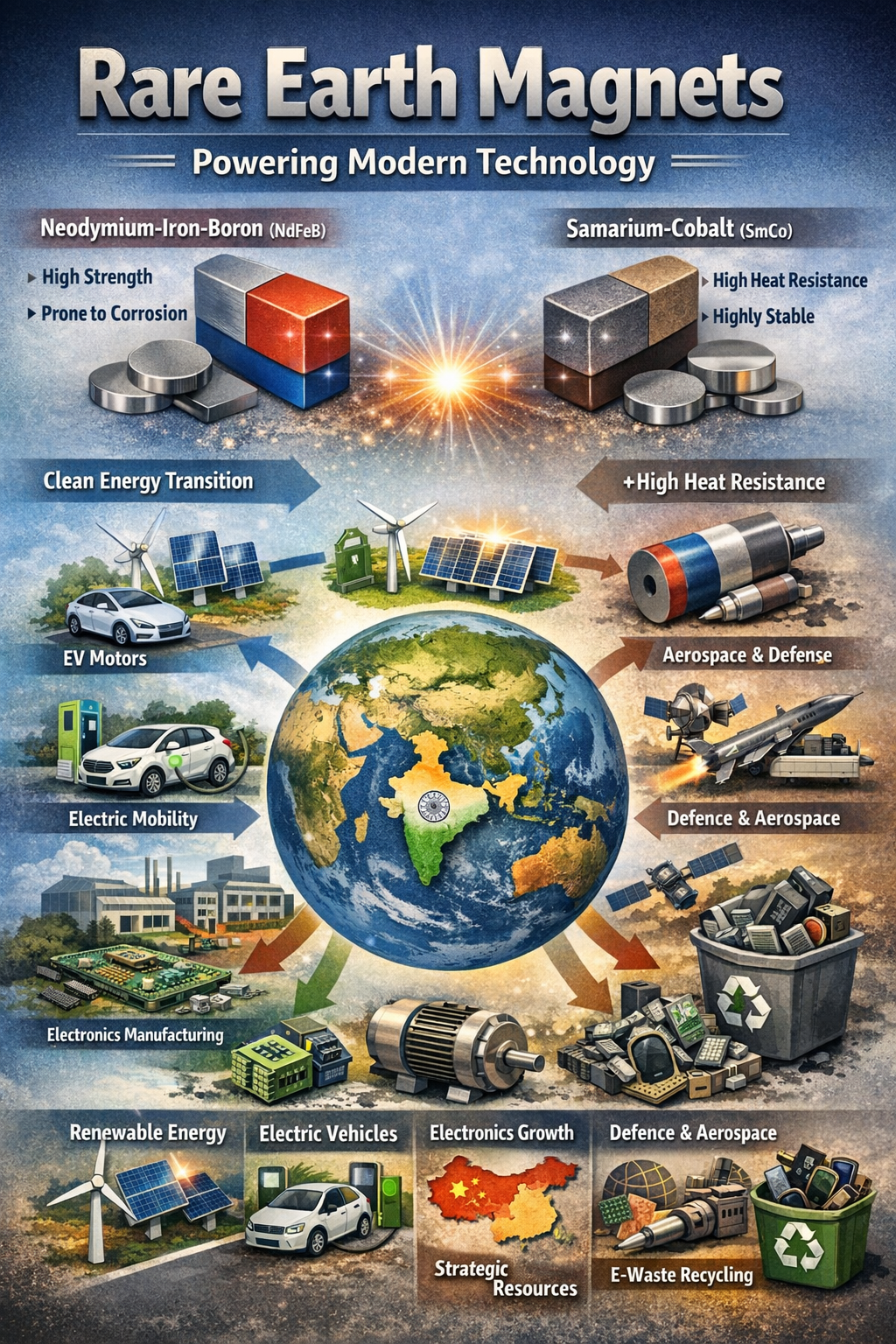

Rare earth magnets are high-performance permanent magnets produced using alloys of rare earth elements, mainly from the lanthanide group. They generate exceptionally strong magnetic fields and are significantly more powerful, often about 10 to 15 times stronger than traditional ferrite or alnico magnets. Their high strength allows modern devices and machines to become smaller, lighter, and more energy efficient.

Neodymium–Iron–Boron (NdFeB) Magnets

Composition

These magnets are made from an alloy of neodymium, iron, and boron. Small quantities of elements such as dysprosium or praseodymium may be added to improve performance at elevated temperatures.

Key Features

NdFeB magnets offer the highest magnetic strength among commercially available permanent magnets. They have strong resistance to demagnetisation and allow compact, lightweight designs.

Advantages

Their high power relative to size makes them ideal for energy-efficient and miniaturised technologies. They are widely used and comparatively economical for large-scale industrial applications.

Limitations

They can lose magnetic strength at high temperatures unless enhanced with additional rare earth elements. These magnets are also susceptible to corrosion and therefore require protective coatings such as nickel or epoxy. Their production depends on critical minerals, making supply chains vulnerable.

Applications

NdFeB magnets are widely used in electric vehicle motors, wind turbine generators, smartphones, earphones, computer drives, cooling systems, robotics, industrial automation, medical imaging equipment, drones, and satellite components.

Samarium–Cobalt (SmCo) Magnets

Composition

SmCo magnets are produced using samarium and cobalt, sometimes with small additions of iron, copper, or zirconium to enhance performance.

Key Features

Although slightly less powerful than NdFeB magnets, they are highly stable under extreme conditions. They offer excellent resistance to corrosion and oxidation and maintain magnetic properties at very high temperatures.

Advantages

These magnets can operate efficiently at temperatures as high as 300–350°C. They perform reliably in harsh environments and are less likely to lose magnetism due to heat, radiation, or chemical exposure.

Limitations

Their production cost is higher because of cobalt supply constraints. They are also brittle and require careful handling during manufacturing and assembly.

Applications

SmCo magnets are used in aerospace and defence systems, jet engines, missile guidance systems, satellites, high-temperature sensors and actuators, oil and gas drilling equipment, specialised medical devices, and high-performance industrial motors.

India’s move to begin rare-earth permanent magnet production marks a crucial shift from resource extraction to strategic manufacturing. Combined with processing parks and recycling initiatives, it can enhance technological sovereignty and support the country’s clean energy and industrial ambitions.

Source: The Hindu

|

Practice Question Q. Rare earth magnets have emerged as strategic materials for clean energy, advanced manufacturing, and national security. Discuss their significance for India. Also examine the challenges in developing a domestic rare earth magnet ecosystem and the steps taken by the government to address them. (250 words) |

Rare earth magnets are high-strength permanent magnets made from alloys of rare earth elements such as neodymium, samarium, and dysprosium, and they are 10–15 times stronger than conventional magnets.

They are essential for electric vehicles, wind turbines, consumer electronics, defence systems, and industrial automation, making them critical for the clean energy transition, digital economy, and national security.

The two major types are Neodymium–Iron–Boron (NdFeB) magnets, known for maximum strength and widespread industrial use, and Samarium–Cobalt (SmCo) magnets, valued for their high temperature stability and resistance to corrosion.

© 2026 iasgyan. All right reserved