Description

Copyright infringement not intended

Picture Courtesy: PIB

Context:

The Union Budget 2026–27 has given a strategic boost to India’s technology ambitions through the launch of India Semiconductor Mission (ISM) 2.0, with an allocation of ₹1,000 crore for FY 2026–27.

What is India Semiconductor Mission (ISM) 2.0?

India Semiconductor Mission 2.0 is the second phase of India’s national semiconductor programme announced in the Union Budget 2026–27 to strengthen domestic chip capabilities. It marks a shift from ecosystem creation to capacity expansion, advanced manufacturing, indigenous design, and supply chain resilience. With a provision of ₹1,000 crore for FY 2026–27, the mission aims to position India as a reliable global semiconductor hub and reduce dependence on imports.

Key focus areas of ISM 2.0:

- Indigenous semiconductor equipment and materials: The mission promotes domestic production of semiconductor manufacturing equipment, specialty chemicals, gases, wafers, and other critical materials to reduce external dependency and build supply chain security.

- Full stack design and Indian IP: ISM 2.0 encourages the development of end-to-end Indian semiconductor intellectual property (IP) through the expansion of the Design Linked Incentive (DLI) ecosystem and support for fabless startups.

- Advanced technology development: A clear technology roadmap has been defined to move toward advanced nodes such as 3 nm and 2 nm, enabling India to participate in next-generation semiconductor manufacturing.

- Industry led research and skill development: The mission supports industry-driven R&D centres, training hubs, and academic partnerships to build a future-ready semiconductor workforce across design, fabrication, and packaging.

- Global supply chain integration: ISM 2.0 aims to integrate India into global semiconductor value chains by attracting investments, strengthening partnerships, and positioning India as a trusted manufacturing destination.

Manufacturing Focus under ISM 2.0:

- Expansion of semiconductor fabs: The mission provides targeted financial support to establish and scale silicon semiconductor fabrication units, with an estimated investment of about ₹4,000 crore during 2026–27 and an expected generation of around 1,500 high-skilled jobs.

- Strengthening ATMP and OSAT ecosystem: ISM 2.0 supports the establishment and expansion of Assembly, Testing, Marking and Packaging (ATMP) and Outsourced Semiconductor Assembly and Test (OSAT) facilities, with about nine units expected to attract nearly ₹11,000 crore in investment and generate approximately 3,000 jobs.

- Diversification into emerging manufacturing segments: The manufacturing strategy also includes support for compound semiconductors, silicon photonics, sensors, discrete devices, and advanced packaging technologies to build a comprehensive and resilient semiconductor production ecosystem.

- Domestic capability targets: Through these efforts, India aims to achieve the capability to design and manufacture chips required for nearly 70–75 per cent of domestic demand by 2029 and to emerge as a leading global semiconductor nation by 2035.

Current status of the Semiconductor market in India:

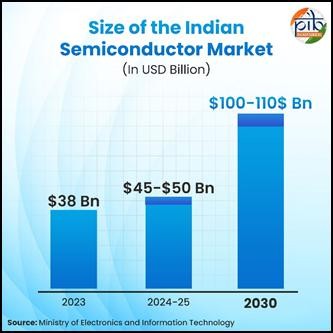

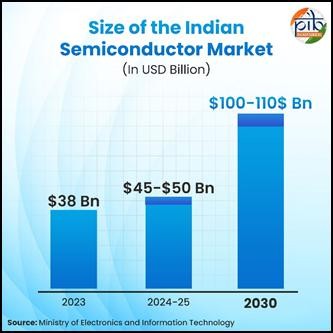

- India’s semiconductor market is expanding rapidly, driven by rising demand for electronics, digital infrastructure, and emerging technologies, with the market valued at around $38 billion in 2023, estimated to reach $45–50 billion during 2024–25, and projected to grow to $100–110 billion by 2030, reflecting strong long-term growth potential.

- Despite rising demand, India currently imports nearly 90–95% of its semiconductor requirements, indicating limited domestic manufacturing capacity and highlighting the strategic need for initiatives such as the India Semiconductor Mission to reduce external dependence.

- India has begun developing its domestic semiconductor ecosystem, with 10 approved projects worth about ₹1.60 lakh crore across multiple states.

- India already has a strong presence in the global semiconductor design segment, with over 20% of the world’s semiconductor design engineers located in the country and several global firms operating major design centres, positioning India as a key hub for chip design and R&D.

- India aims to achieve the capability to design and manufacture chips for nearly 70–75% of its domestic demand by 2029.

Picture Courtesy: PIB

Importance of Semiconductor mission:

- Economic stability: Semiconductors support critical sectors such as energy systems, financial networks, telecommunications, manufacturing, healthcare, transport, and satellites, and a reliable domestic supply is essential to ensure uninterrupted economic activity across these sectors.

- Reducing import dependence: India currently relies heavily on imported chips despite being a major consumer market, and the mission aims to build domestic capacity so that the country can design and manufacture chips for nearly 70–75% of its domestic requirements by 2029.

- Managing supply risks: The COVID-19 disruption exposed global vulnerabilities as semiconductor shortages affected more than 169 industries worldwide, and domestic manufacturing under the mission is intended to protect India from similar external shocks in the future.

- Addressing global concentration: The global semiconductor industry is dominated by a few countries, with Taiwan alone producing over 60% of global chips and nearly 90% of advanced semiconductors, making supply chains vulnerable and highlighting the need for India to develop its own capabilities.

- Supporting market growth: India’s semiconductor demand is rising rapidly, with the market growing from $38 billion in 2023 to an estimated $45 – 50 billion in 2024 – 25, and expected to reach $100 – 110 billion by 2030, making domestic production economically necessary.

- Building manufacturing capacity: Under the broader semiconductor programme, 10 projects worth ₹1.60 lakh crore across six states have already been approved, which will expand fabrication, packaging, and testing infrastructure and strengthen the domestic ecosystem.

- Creating employment: For 2026–27, the programme is expected to generate around 4,500 direct jobs, including 1,500 jobs in semiconductor fabs and 3,000 jobs in ATMP and related units, contributing to high-skilled employment growth.

- Strengthening design capability: The Design Linked Incentive ecosystem currently supports 24 startups, has enabled ₹430 crore in venture funding, and has engaged 67,000 students and over 1,000 engineers, thereby strengthening India’s innovation and intellectual property base.

Challenges of Semiconductor mission:

- High investment burden: Semiconductor manufacturing requires very large capital commitments and long gestation periods, and even under the current programme only one semiconductor fab with an investment target of ₹4,000 crore for 2026–27 is being supported, indicating the scale of financial constraints.

- Limited manufacturing base: Despite progress, India’s manufacturing ecosystem is still at an early stage, with 10 approved projects worth ₹1.60 lakh crore across six states (as of December 2025), which remains modest compared to the scale and maturity of global semiconductor hubs.

- Technology dependence: Advanced semiconductor technologies are concentrated in a few countries, and India is still developing capabilities for advanced nodes such as 3 nm and 2 nm, making access to cutting-edge manufacturing technology a significant challenge.

- Supply chain dependence: The global semiconductor industry is highly concentrated geographically, with Taiwan producing over 60% of global chips and nearly 90% of advanced semiconductors, which limits diversification and keeps India dependent on external ecosystems for advanced components and technologies.

Major initiatives for Semiconductor talent development:

- Chips to Start-up Programme: The Chips to Start-up initiative provides widespread access to advanced Electronic Design Automation (EDA) tools across 397 universities and startups, enabling students and researchers to gain hands-on experience in chip design, while designers from more than 46 institutions have already designed and fabricated 56 chips at the Semiconductor Laboratory in Mohali, thereby strengthening practical learning and early-stage innovation.

- SMART Lab at NIELIT Calicut: The Skilled Manpower Advanced Research and Training (SMART) Lab at NIELIT Calicut aims to build large-scale technical capacity by targeting the training of one lakh engineers nationwide, of which over 62,000 engineers have already been trained, significantly expanding India’s skilled workforce in semiconductor technologies.

- Industry partnership with Lam Research: India has partnered with Lam Research to implement a large-scale training programme in nanofabrication and process engineering, particularly for Assembly, Testing, Marking and Packaging (ATMP) and advanced packaging facilities, with the initiative aiming to develop 60,000 specialised professionals over the next ten years.

- Future Skills PRIME initiative: The FutureSkills PRIME programme, a joint initiative of MeitY and NASSCOM, offers industry-aligned online courses in emerging technologies including semiconductors, enabling learners to access flexible training, upgrade their skills, and earn recognised certifications that support India’s goal of becoming a global hub for advanced technology talent.

Conclusion:

India Semiconductor Mission 2.0 marks a strategic shift from ecosystem creation to capability expansion by strengthening domestic manufacturing, deepening design and innovation, and building a skilled workforce, thereby laying the foundation for technological self-reliance, supply chain resilience, and India’s emergence as a trusted global semiconductor hub.

Source: PIB

|

Practice Question

Q. India Semiconductor Mission 2.0 represents a strategic push towards technological sovereignty and supply chain resilience. Discuss. (250 words)

|

Frequently Asked Questions (FAQs)

India Semiconductor Mission 2.0 is the second phase of India’s semiconductor programme launched in the Union Budget 2026–27 to strengthen domestic capabilities in chip manufacturing, design, equipment, materials, and skill development.

The mission focuses on domestic semiconductor manufacturing, development of indigenous equipment and materials, full-stack Indian semiconductor intellectual property, industry-led research, and large-scale talent development.

India’s semiconductor market, valued at about $38 billion in 2023, is expected to grow to $100–110 billion by 2030 due to rising demand across multiple sectors.