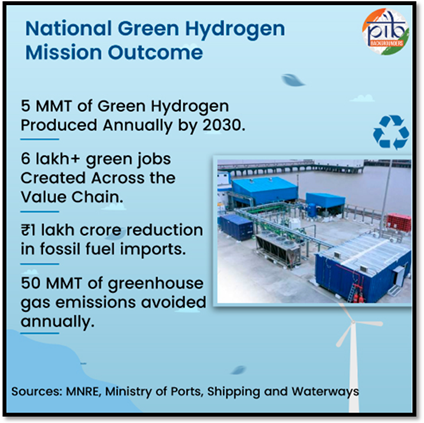

India’s National Green Hydrogen Mission (NGHM) aims to position the country as a global leader in green hydrogen by 2030. Green hydrogen, produced using renewable energy, offers a clean alternative to fossil fuels, helping decarbonize hard-to-abate sectors like steel, fertilizers, mobility, and shipping. The Mission focuses on scaling production, promoting domestic manufacturing, fostering R&D through public-private partnerships, developing port-based hydrogen hubs, and implementing certification standards. Despite challenges like high costs, infrastructure gaps, and technology readiness, strategic policy support, financial incentives, and skill development are driving India’s transition toward a sustainable, low-carbon, and energy-secure future.

Copyright infringement not intended

Picture Courtesy: PIB

India’s energy transition is entering a decisive phase, as the country reduces its dependence on fossil fuels and increases domestic clean energy production. This is in line with its vision of becoming a developed nation by 2047 and achieving Net Zero by 2070.

|

Must Read: GREEN HYDROGEN | GREEN HYDROGEN STANDARDS | PURE GREEN HYDROGEN | GLOBAL HYDROGEN RACE & INDIA'S STRATEGIC ROLE | |

Green Hydrogen is Hydrogen produced using renewable energy, such as solar or wind power, instead of fossil fuels. In this process water is split into hydrogen and oxygen through electrolysis, using electricity from solar panels or wind turbines. According to standards notified by Govt of India, Hydrogen made this way is considered “green” if the total emissions from the process are very low, not more than 2 kg of CO₂ equivalent for every 1 kg of Hydrogen produced. Green Hydrogen can also be produced by converting biomass (like agricultural waste) into hydrogen, as long as emissions remain below the same limit.

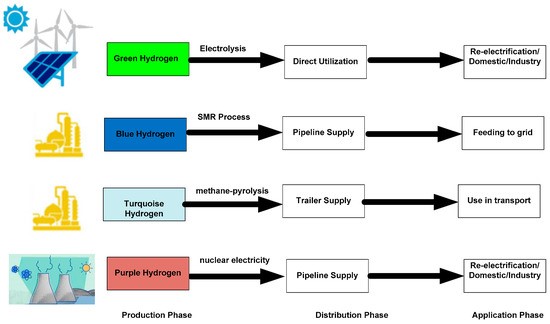

Grey Hydrogen: This is the most common type used today. It’s produced from fossil fuels, usually natural gas through a process called steam methane reforming (SMR), or from coal through gasification. Both methods release a lot of carbon dioxide into the atmosphere.

Picture Courtesy: MDPI

Blue Hydrogen: Blue hydrogen starts from the same process as grey hydrogen—using natural gas or coal—but adds carbon capture and storage (CCS) technology. The CO₂ produced during hydrogen generation is trapped and stored underground instead of being released.

It’s often described as a “bridge fuel”—less polluting than grey hydrogen, but not completely clean since capturing all emissions is still technically and economically difficult.

Picture Courtesy: MDPI

Green Hydrogen: Green hydrogen is made by splitting water (H₂O) into hydrogen and oxygen using electrolysis powered by renewable energy—for example, from solar panels or wind turbines.

Because no fossil fuels are used and the electricity is renewable, the process generates little to no carbon emissions. This is the cleanest form of hydrogen and is central to global net-zero and energy transition strategies.

Turquoise Hydrogen: This is produced through methane pyrolysis, where natural gas is split into hydrogen and solid carbon rather than carbon dioxide.

If powered by renewable electricity, this method could become a low-carbon alternative, since solid carbon is easier to handle than gaseous CO₂.

It’s still in early stages of research and not widely commercialized.

Black Hydrogen and 🟫 Brown Hydrogen: Both are made from coal, but the difference lies in the coal type: black hydrogen from hard (bituminous) coal, brown hydrogen from lignite (soft) coal.

These are the most carbon-intensive forms of hydrogen, producing large amounts of CO₂, and are being phased out in most clean energy plans.

Yellow Hydrogen: This hydrogen is made through electrolysis powered by grid electricity. Its carbon footprint depends entirely on the mix of power in the grid. If the grid uses coal, it’s not very clean; if it’s mostly renewable, it approaches green hydrogen in emissions profile.

Pink (or Purple/Red) Hydrogen: Produced using nuclear power for the electricity or heat needed in electrolysis. Since nuclear power is low-carbon, pink hydrogen is also considered clean, and it offers the advantage of steady, round-the-clock production, unlike renewables which are intermittent.

White Hydrogen: This refers to naturally occurring hydrogen found underground in geological formations. It’s produced by natural chemical reactions within the Earth’s crust, not by human industry.

Exploration is just beginning, but it could one day become a natural, zero-emission source of hydrogen if extraction proves safe and viable.

Picture Courtesy: MDPI

The National Green Hydrogen Mission (NGHM) is India’s flagship initiative to make the country a global hub for green hydrogen production, usage, and export.

It was launched in January 2023 by the Ministry of New and Renewable Energy (MNRE) and represents a central part of India’s energy transition strategy to achieve Net Zero emissions by 2070.

Strategic Interventions for Green Hydrogen Transition (SIGHT) Programme: This is the core financial and industrial driver of the Mission. Conceptually, it aims to create an enabling market for green hydrogen by:

Pilot Projects: This component focuses on demonstration and learning. It supports real-world pilot projects across sectors such as:

The purpose is to test technology, understand practical challenges, and build confidence in hydrogen’s use across industries.

Research, Development, and Innovation (R&D): At the heart of the Mission is a belief that innovation will drive affordability and scale. This component invests in:

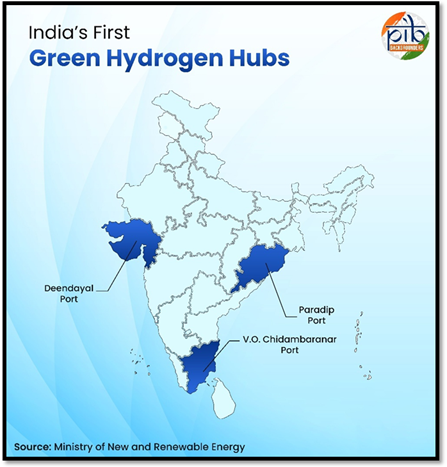

Enabling Infrastructure and Ecosystem Development: This component focuses on creating the physical and institutional backbone for the hydrogen economy. It includes:

Picture Courtesy: PIB

Industrial Sector: Industries are among the largest energy consumers and emitters of carbon dioxide. Green hydrogen offers a clean alternative to fossil fuels and carbon-based feedstocks.

Mobility and Transport: Green hydrogen can fuel transportation modes that are difficult to electrify through batteries alone.

Power and Energy Systems: Hydrogen can act as a bridge between renewable power generation and energy storage.

Residential and Commercial Uses: While still limited, hydrogen could eventually be used in:

Picture Courtesy: PIB

High Production Costs: Green hydrogen production is still more expensive than fossil-fuel-based hydrogen, mainly due to the cost of electrolysers and renewable electricity. In India, green hydrogen costs around ₹400–500 per kg, compared to ₹150–200 per kg for grey hydrogen from natural gas.

Infrastructure Limitations: Hydrogen requires dedicated storage, transport, and refuelling infrastructure due to its low density and high flammability. Road transport pilots in India are limited to 9 refuelling stations across 10 routes, constraining large-scale adoption.

Technological Challenges: Hydrogen technologies, especially fuel cells, electrolysers, and storage systems, are still maturing. Steel sector pilots using hydrogen-based iron reduction require new furnace designs and careful safety protocols.

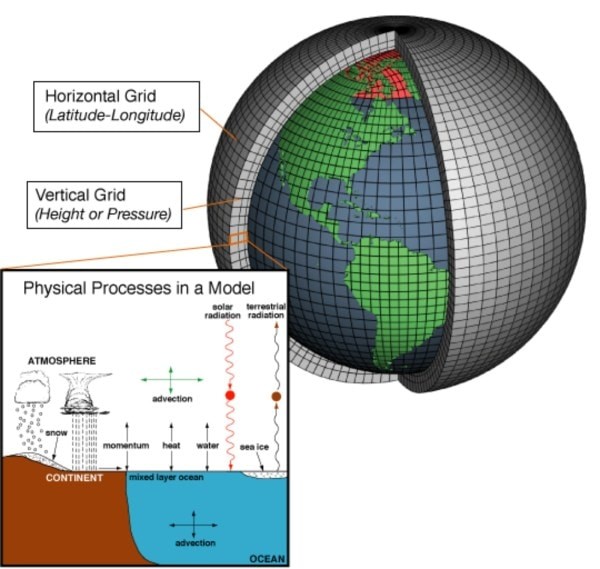

Renewable Energy Dependence: Green hydrogen is only as clean as the renewable energy powering it. Limited renewable capacity or intermittency reduces efficiency and increases costs. Offshore wind or solar energy in certain regions may be seasonal, limiting continuous hydrogen production.

Regulatory and Policy Hurdles: Hydrogen markets require clear standards, safety codes, and certification frameworks to ensure adoption and trade. Without the Green Hydrogen Certification Scheme, buyers cannot verify emission compliance.

Supply Chain and Storage Issues: Hydrogen is highly volatile and has low volumetric density, making long-distance transport and storage difficult. Compressing or liquefying hydrogen for export requires specialized technology, which is capital-intensive.

Green hydrogen is poised to become a cornerstone of India’s clean energy transition, enabling decarbonization of hard-to-abate sectors, reducing fossil fuel dependence, and driving industrial growth. With strategic investment in production, infrastructure, technology, policy support, and skill development, India can emerge as a global leader in green hydrogen, fostering a sustainable, self-reliant, and low-carbon economy by 2030 and beyond.

Source: PIB

|

Practice Question Q. Green hydrogen can play a pivotal role in India’s energy transition and industrial decarbonization. Critically examine the opportunities and challenges associated with its production and use. How does the National Green Hydrogen Mission (NGHM) aim to address these challenges? (250 words) |

Green hydrogen is hydrogen produced by splitting water (electrolysis) using electricity from renewable energy sources like solar or wind. It is considered “green” if lifecycle emissions are very low (≤2 kg CO₂e per kg H₂).

© 2026 iasgyan. All right reserved