India’s plan to extract rare earths from fly ash under Atma Nirbhar Bharat faces criticism as techno-economically unviable due to very low REE content. Experts warn it undermines fly ash reuse and creates waste challenges, advocating instead for sustainably exploiting high-grade monazite sands, with fly ash extraction limited to long-term research.

Context

The government is studying whether to extract Rare Earth Elements (REEs) from fly ash or focus on traditional resources to support the 'Atma Nirbhar Bharat' initiative, balancing technology, economics, and environment.

What are Rare Earth Elements (REEs)?

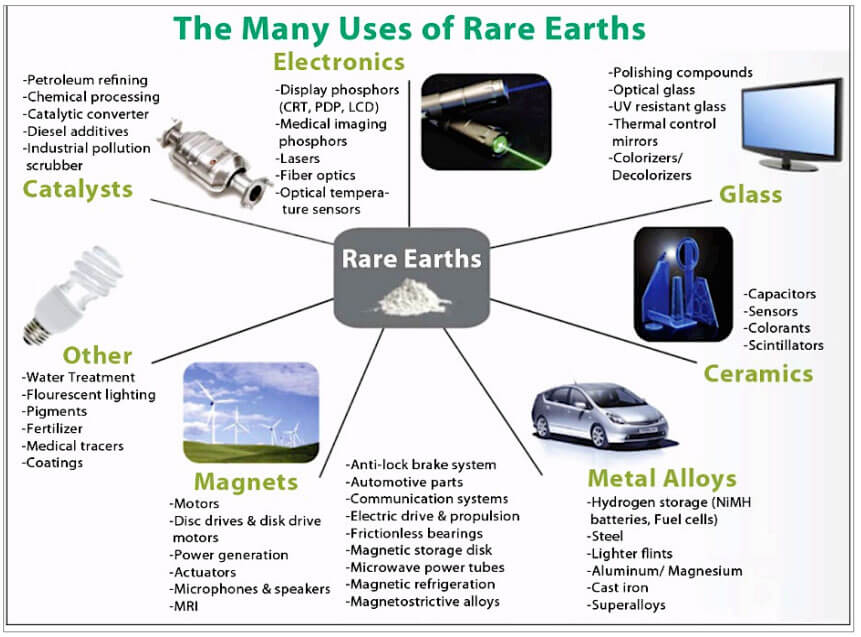

Rare Earth Elements (REEs) are a group of 17 chemically similar metallic elements, essential for high-tech devices, and often called the "vitamins of modern industry."

The 17 Elements

The group includes the 15 lanthanides (elements with atomic numbers 57 to 71) plus scandium and yttrium.

Key Characteristics

Major Applications

Strategic Importance for India

Green Energy: Elements like Neodymium and Dysprosium are vital for permanent magnets used in wind turbines and Electric Vehicle (EV) motors.

Defence & Aerospace: Essential for precision-guided weapons, drones, and advanced avionics.

Advanced Electronics: Used in smartphones, laptops, and medical equipment like MRI machines.

Geopolitical Security: China dominates the global REE market, controlling over 85% of production and processing (Source: Harvard International Review).

The Fly Ash Proposal vs Monazite Sands

The debate centers on whether to extract Rare Earth Elements (REE) from thermal power plant fly ash or to increase extraction from India's abundant monazite beach sand reserves.

What is Fly Ash?

Fly ash is a fine, powdery byproduct composed of silica, alumina, and iron oxide, generated from burning pulverized coal in thermal power plants.

Captured from flue gases, this pozzolanic material is widely used as a sustainable, cost-effective substitute for Portland cement in concrete, enhancing durability, reducing permeability, and increasing strength.

In FY 2024-25, India achieved a fly ash utilisation rate of approximately 98%, with 332.63 million tonnes used out of 340.11 million tonnes generated. (Source: PIB)

The Ash Utilization Notification, 2021, mandates 100% utilisation, making it a successful 'Waste to Wealth' model.

Arguments Against Extracting REEs from Fly Ash

Extremely Low Concentration

The concentration of REEs in Indian fly ash is a minuscule 0.04%. This makes the process highly inefficient compared to other sources.

Economic Non-Viability

The high cost of chemicals and complex processes required to extract trace amounts of REEs would result in a significant financial loss.

Environmental Liability

Chemical leaching destroys fly ash's pozzolanic properties, making the remaining 99.96% inert and useless for construction, thus turning a valuable resource back into a massive waste disposal problem.

Policy Contradiction

This proposal directly conflicts with the successful and legally mandated policy of 100% fly ash utilisation in the construction sector.

Fly Ash vs Monazite Sands for REE Extraction

|

Parameter |

Fly Ash |

Monazite Sands |

|

REE Concentration |

Extremely Low (approx. 0.04%) |

Very High (55% to 60%) |

|

Economic Viability |

Prohibitively expensive; leads to financial loss. |

Economically viable with established processes. |

|

Primary Challenge |

Techno-economic feasibility and creation of new waste. |

Managing radioactivity (Thorium) and environmental impact of mining. |

|

Current Status |

Proposed as a new source; lacks proven technology at scale. |

India's primary domestic source; processed by IREL (India) Limited. |

Challenges with Monazite Processing

India possesses the world's third-largest rare earth reserves but struggles with production, ranking seventh globally.

Radioactivity: Monazite contains Thorium, a radioactive element. This places its mining and processing under the strict regulations of the Department of Atomic Energy (DAE), limiting private participation.

Environmental & Social Concerns: Beach sand mining faces local opposition due to its potential impact on coastal ecosystems.

Way Forward for India

Prioritise High-Grade Resources: Sustainably harness India's monazite reserves by modernizing IREL facilities and developing safer processing technologies.

Fly Ash as a Long-Term R&D Project: Prioritize Rare Earth Element (REE) extraction from fly ash as a strategic research mission for developing indigenous, eco-friendly methods, not an immediate commercial venture.

Embrace a Circular Economy: Fly ash technology must yield residual material suitable for construction, avoiding new waste streams.

Ensure Policy Coherence: Mineral security goals should not jeopardize the successful 'Waste to Wealth' fly ash model; a unified national policy is required to harmonize both aims.

Learn lessons from global practices

Conclusion

India should prioritize strengthening high-grade monazite processing for Rare Earth Elements self-reliance while treating fly ash extraction as a long-term research goal to avoid new environmental risks.

Source: THE HINDU

|

PRACTICE QUESTION Q. Consider the following statements about the management of fly ash in India: 1. The Ministry of Environment, Forest and Climate Change (MoEF&CC) mandates 100% utilisation of ash by thermal power plants. 2. The majority of utilised fly ash is used for manufacturing fertilisers and agricultural inputs. 3. Chemical processing of fly ash for mineral extraction enhances its pozzolanic properties for construction. Which of the statements given above is/are correct? a) 1 only b) 1 and 2 only c) 2 and 3 only d) 1, 2 and 3 Answer: (a) Explanation: Statement 1 is correct: The Ministry of Environment, Forest and Climate Change (MoEF&CC) issued the Ash Utilization Notification, 2021, which mandates 100% utilization of fly ash by coal or lignite-based thermal power plants (TPPs) within prescribed timelines. Statement 2 is incorrect: While fly ash is used in agriculture for soil health improvement, its use in fertilizers and agricultural inputs is not the majority. The vast majority of utilized fly ash in India is consumed by the construction sector, specifically for manufacturing cement and bricks. Statement 3 is incorrect: Chemical processing extracts minerals (like alumina or silica) from fly ash for resource recovery, not to boost its pozzolanic properties. Fly ash is inherently pozzolanic due to its silica and alumina, reacting naturally with calcium hydroxide and water to form cementitious compounds. |

Rare Earth Elements (REEs) are a group of 17 metallic elements crucial for modern technology, including the 15 lanthanides plus scandium and yttrium, known for unique magnetic, optical, and catalytic properties, vital for electronics, clean energy (EVs, wind turbines), defense, and medical devices, despite being common but hard to extract in pure forms.

The primary argument is its economic and environmental non-viability. Indian fly ash has an extremely low REE concentration (around 0.04%), making the extraction process prohibitively expensive. Furthermore, the chemical process would destroy the fly ash's useful properties for construction, turning a valuable resource back into a massive waste disposal problem.

Fly ash is a fine powder by-product from burning coal in thermal power plants. Under the 'Waste to Wealth' model, India has achieved a 98% utilisation rate. It is primarily used as a secondary raw material in the construction sector for building roads, flyovers, cement, bricks, and tiles.

Monazite sand is a reddish-brown to black, heavy, and often radioactive mineral deposit, primarily composed of rare-earth phosphates (cerium, lanthanum, neodymium) and thorium. It is a major commercial source for rare-earth elements used in magnets and electronics, as well as thorium, a potential nuclear fuel, usually found in coastal placer deposits.

© 2026 iasgyan. All right reserved