Description

Disclaimer: Copyright infringement not intended.

Context

Hyderabad based Raghu Vamsi Machine Tools Private Limited, a leading player in the aerospace and Defence industry, has launched its fully indigenous Micro Turbojet Engine “INDRA RV25: 240N” in alignment with the Atma Nirbhar Bharat.

Details

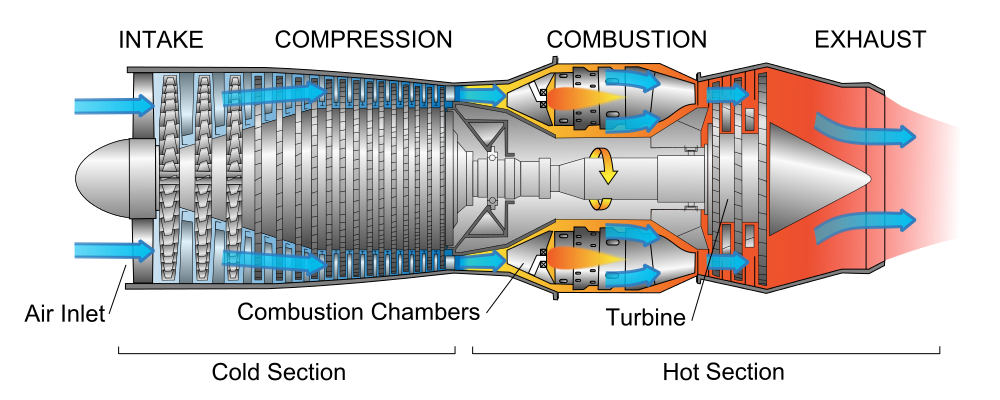

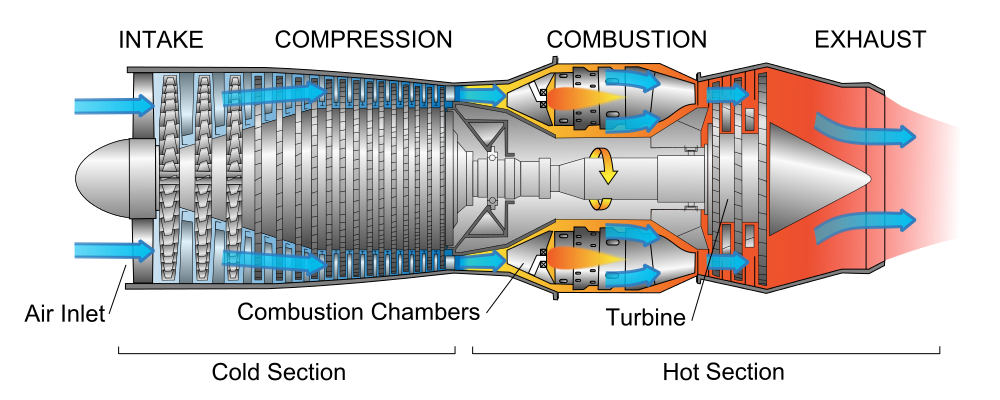

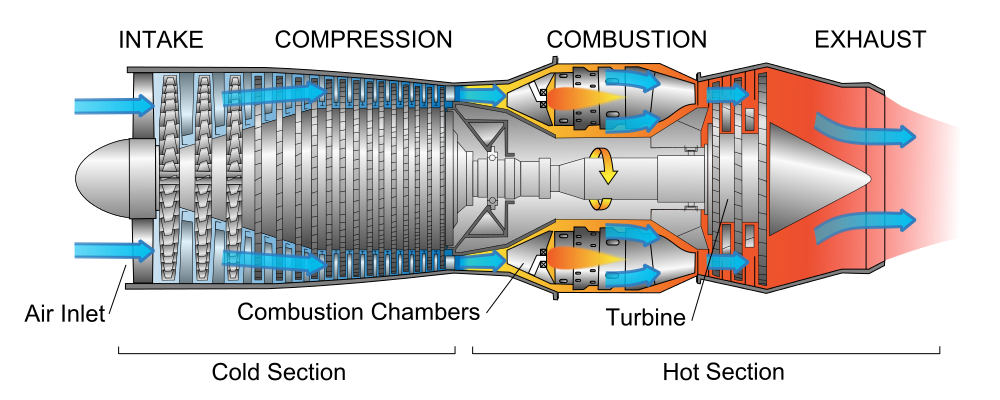

Introduction to Turbojet Engines

- Turbojet engines are a type of air-breathing jet engine that powers aircraft by generating thrust through the continuous intake, compression, combustion, and exhaust of air.

- They played a pivotal role in the advancement of aviation technology, particularly during the mid-20th century, and remain crucial components of military and civilian aircraft today.

Components and Working Principle

Air Intake

- Function: Turbojet engines begin the process by drawing in atmospheric air through an intake, where it is compressed and directed into the engine.

- Design: Intake designs vary depending on factors such as aircraft speed, altitude, and engine configuration.

Compressor

- Function: The compressor increases the pressure and density of the incoming air before it enters the combustion chamber.

- Types: Turbojet engines typically feature axial-flow compressors, which consist of multiple stages of rotating blades and stationary stator vanes.

Combustion Chamber

- Function: In the combustion chamber, fuel is injected and mixed with the compressed air, leading to combustion.

- Ignition: Combustion is initiated by igniters or spark plugs, creating a continuous flame.

- Temperature Control: Maintaining optimal temperatures within the combustion chamber is critical for engine efficiency and longevity.

Turbine

- Function: The turbine extracts energy from the hot, high-pressure gases produced during combustion to drive the compressor and other engine accessories.

- Blade Design: Turbine blades are designed to withstand high temperatures and rotational speeds.

Exhaust Nozzle

- Function: The exhaust nozzle directs the hot exhaust gases rearward, accelerating them to produce thrust according to Newton's third law of motion.

- Variable Geometry: Some turbojet engines feature variable geometry nozzles to optimize performance across different flight conditions.

Advantages

- High Speed: Turbojet engines are capable of powering aircraft to high speeds, making them suitable for supersonic and hypersonic flight.

- Simplicity: Compared to more complex engines like turbofans, turbojet engines have relatively simple designs, which can translate to lower maintenance requirements.

- Power-to-Weight Ratio: Turbojet engines offer excellent power-to-weight ratios, making them suitable for high-performance aircraft.

Limitations

- Fuel Efficiency: Turbojet engines tend to have lower fuel efficiency compared to more modern engine types like turbofans.

- Thrust at Low Speeds: Turbojet engines are less efficient at low speeds and altitudes, limiting their suitability for subsonic flight regimes.

- Noise: Turbojet engines can produce significant noise, particularly during takeoff and high-thrust operations.

Applications

- Turbojet engines have historically been used in military aircraft for their high-speed capabilities and agility. Examples include fighter jets like the F-15, F-16, and MiG-21.

- Turbojet engines have powered numerous supersonic and hypersonic aircraft, including the Concorde and experimental research vehicles like the X-15 and SR-71 Blackbird.

- Turbojet engines are commonly employed in cruise missiles due to their compact size, simplicity, and ability to sustain high speeds over long distances.

Introduction to Engines

- Engines are devices designed to convert various forms of energy into mechanical work.

- They play a critical role in powering vehicles, machinery, and numerous industrial processes.

Types of Engines

Internal Combustion Engines

- Spark Ignition (SI) Engines:

- Commonly used in automobiles.

- Fuel-air mixture is ignited by a spark plug.

- Examples include gasoline engines.

- Compression Ignition (CI) Engines:

- Also known as diesel engines.

- Air is compressed until it reaches a high temperature, causing fuel injection to ignite spontaneously.

- Widely used in trucks, buses, and some passenger cars.

Gas Turbine Engines

- Turbojet Engines:

- Found in early jet aircraft.

- Utilize the principle of compressing air, mixing it with fuel, combusting the mixture, and expelling the exhaust gases at high speed to generate thrust.

- Turbofan Engines:

- Commonly used in modern commercial aircraft.

- Feature a large fan at the front, which bypasses a significant portion of air around the core engine, improving efficiency and reducing noise.

Steam Engines

- Historically significant in powering locomotives and early industrial machinery.

- Operate by converting the thermal energy of steam into mechanical work through the expansion of steam in a piston or turbine.

Stirling Engines

- Utilize cyclic compression and expansion of a working fluid, such as air or helium, to generate mechanical work.

- Known for their high efficiency and low noise levels, often used in applications requiring quiet operation, such as solar power generation and submarines.

Rocket Engines

- Used in spacecraft and missiles.

- Employ the principle of reaction propulsion, expelling high-velocity exhaust gases to generate thrust.

Working Principles

Internal Combustion Engines

- Intake: Air and fuel are drawn into the combustion chamber.

- Compression: The mixture is compressed to increase its temperature and pressure.

- Combustion: Fuel is ignited, leading to rapid combustion and the generation of high-pressure gases.

- Expansion: The high-pressure gases expand, driving pistons in reciprocating engines or turbines in rotary engines.

- Exhaust: The spent gases are expelled from the engine.

Gas Turbine Engines

- Air Intake: Atmospheric air is compressed.

- Compression: The compressed air is mixed with fuel and ignited in the combustion chamber.

- Expansion: The hot gases produced by combustion expand rapidly, driving turbine blades.

- Thrust Generation: The high-speed exhaust gases exiting the turbine generate thrust.

Other Engine Types

- Steam engines utilize the expansion of steam to drive pistons or turbines.

- Stirling engines operate on the cyclic compression and expansion of a working fluid.

- Rocket engines expel high-velocity exhaust gases to produce thrust through reaction propulsion.

.jpg)

Conclusion

Turbojet engines have played a pivotal role in the development of aviation, enabling high-speed flight and military superiority. While newer engine types like turbofans have largely supplanted them in commercial aviation, turbojet engines remain essential for certain military and specialized applications, with ongoing research aimed at enhancing their performance, efficiency, and environmental sustainability.

|

PRACTICE QUESTION

Q. Compare and contrast the working principles of Internal Combustion Engines, Gas Turbine Engines, and Turbojet Engines. (150 words)

|