Description

Source: IndianExpress

Disclaimer: Copyright infringement not intended

Context

- On May 9, 2024, ISRO successfully tested a liquid rocket engine, PS4, for the fourth stage of the Polar Satellite Launch Vehicle (PSLV), manufactured using additive manufacturing technology, commonly known as 3D printing.

- This advancement showcases ISRO's commitment to innovation and efficiency in space technology.

Details

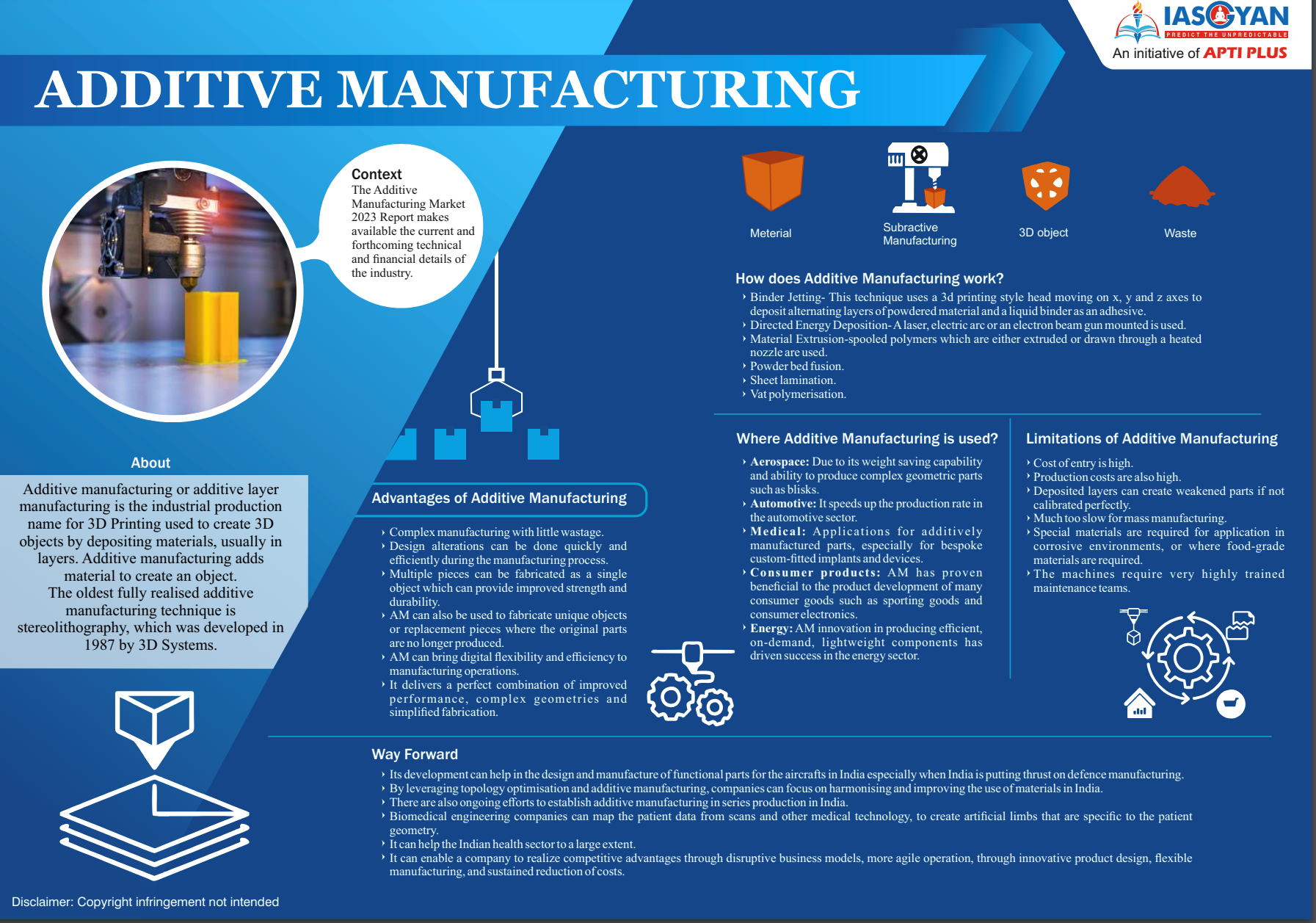

- 3D printing is an additive manufacturing process that constructs three-dimensional objects layer by layer using computer-created designs.

- Designers create a 3D model of the object using Computer-Aided Design (CAD) software, which is then sent to a 3D printer. The printer builds the object layer by layer, stacking materials such as plastic, composites, or bio-materials to form the final product.

- Unlike subtractive manufacturing, where material is removed from a solid block to create an object (e.g., sculpting), 3D printing adds material layer by layer to form the desired shape.

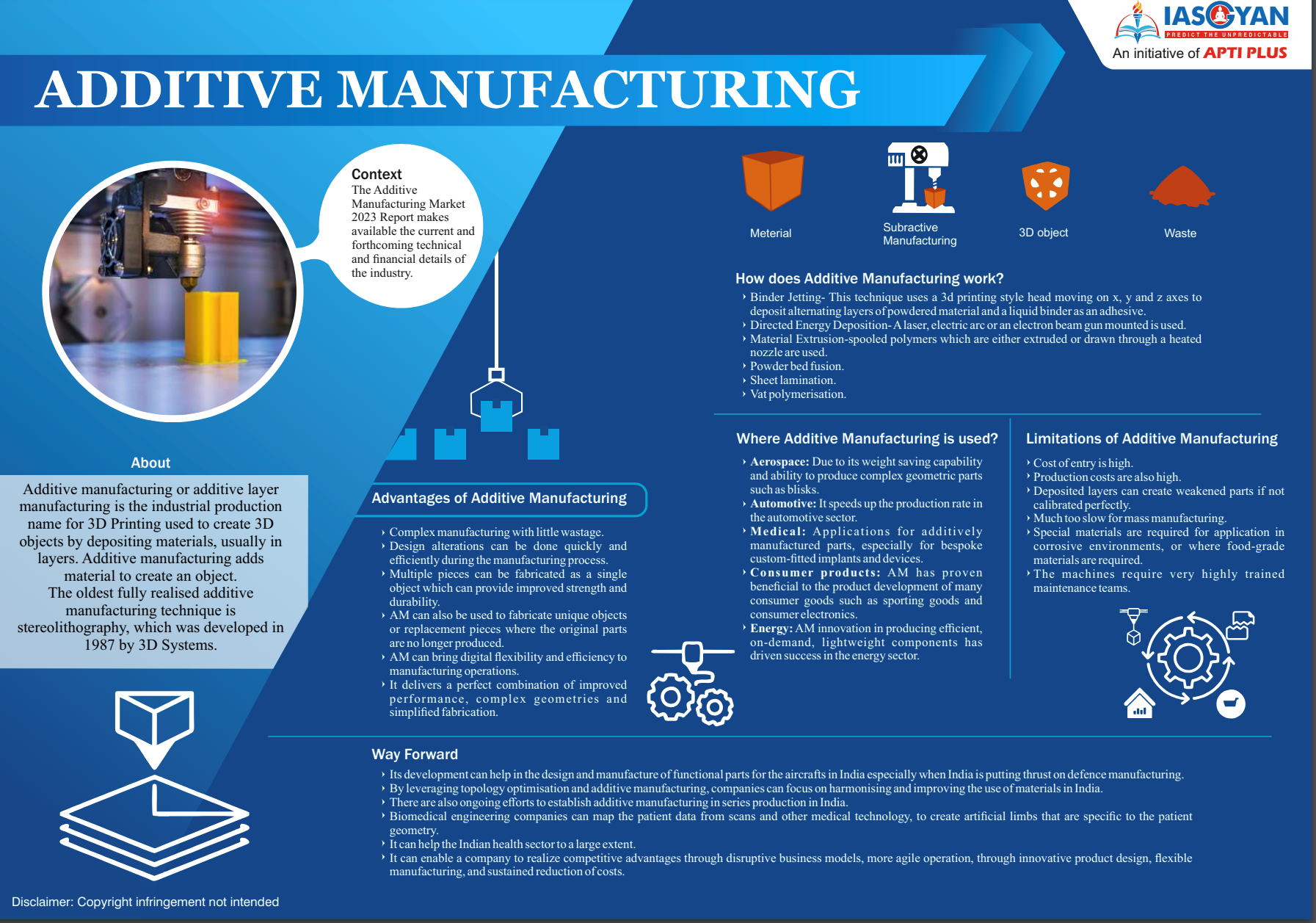

Advantages of 3D Printing

- Complexity: 3D printing enables the creation of intricate and complex shapes that would be challenging or impossible to achieve with traditional manufacturing methods.

- Efficiency: By eliminating the need for multiple parts and weld joints, 3D printing reduces material waste and production time.

- Customization: It allows for customized designs and adaptations, catering to specific requirements with minimal adjustments.

- Cost-Effectiveness: Despite initial setup costs, 3D printing can be cost-effective for small to medium-scale production runs, especially when considering savings in material and labor.

Application in ISRO's PS4 Engine

- Redesign: ISRO redesigned the PS4 engine for production using 3D printing technology.

- Simplification: By leveraging 3D printing, ISRO reduced the number of parts in the engine from 14 to a single piece, eliminating 19 weld joints.

- Material Savings: The use of 3D printing saved 97% of raw material compared to traditional manufacturing methods.

- Time Efficiency: Overall production time was reduced by 60%, showcasing the efficiency gains achieved through additive manufacturing.

Must read articles:

3-D Printing

Satellite Launch Vehicles

Sources:

IndianExpress

|

PRACTICE QUESTION

Q. Discuss the significance of additive manufacturing, particularly 3D printing, in the context of industrial development and innovation. Highlight its potential impact on various sectors, challenges, and future prospects. (150 words)

|